Flywoo X30 PCBA Super Hydrophobic Clear Protective Spray

€25,99

An ultra-thin superhydrophobic coating reliably protects electronics from water, moisture, corrosion and short circuits, while not interfering with cooling and helping to dissipate heat more effectively.

![]() 1 – 2 days

1 – 2 days

In stock

Flywoo X30 waterproof super hydrophobic invisible spray creates a highly effective protective coating for electronic modules and provides reliable daily protection against moisture.

Instructions for use

1. Cleaning:

Before applying, it is necessary to thoroughly clean dust, grease and other dirt from the surface.

2. Recoating:

This spray is great for repeated use. If you need to refresh the coating, simply clean the surface and spray again in the same area.

Notes:

1. Allow the previous coat to dry completely before spraying the next coat.

2. To achieve the best waterproof effect, it is recommended to spray 2-3 layers.

3. Shake the bottle well before use to ensure the liquid is uniform.

4. After spraying, the surface dries within 2-3 minutes and can be used daily.

5. Do not allow powered electronics (boards) to be submerged in water for long periods of time.

6. Use a special electronic circuit board cleaner to properly prepare the surface.

Scope

• For all electronic modules and boards.

(for flight controllers, speed controllers, video transmitters, O3, etc.)

• For glass surfaces, such as lenses.

(effectively prevents water droplets from accumulating, but may reduce transparency by about 30 %. If the result is not satisfactory, the coating can be cleaned)

• For all panel connections.

• For battery connections.

Specification:

• Capacity: 56.7 g.;

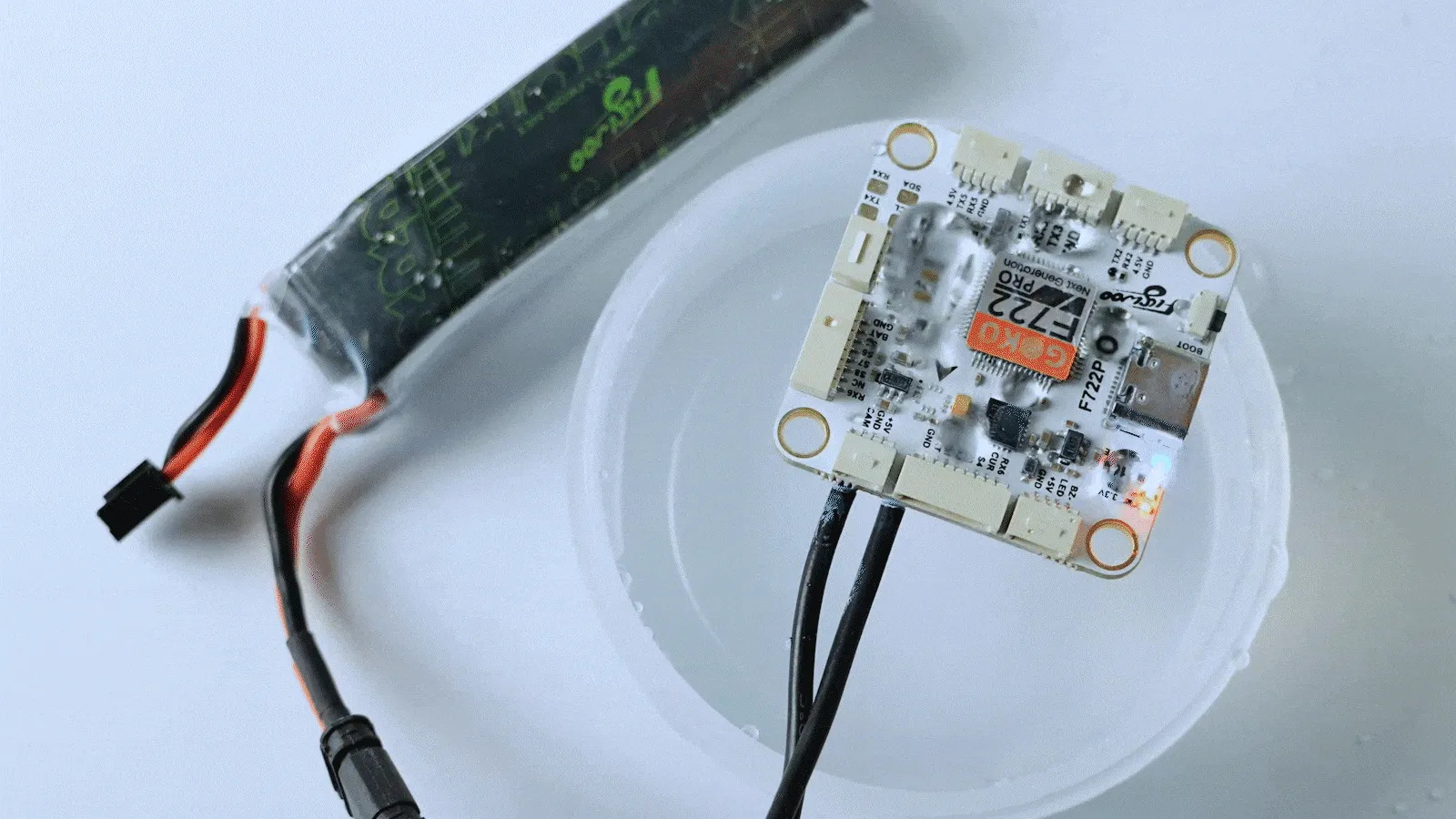

(for example: for the Flywoo GOKU F722 PRO Mini V2 20×20 flight controller, spraying both sides 3 times, it uses about 2.5g)

• Color: milky white;

• Relative density (25 °C): 1.56 ± 0.3 g/cm³;

• Water repellency angle: >160°;

• Material: superhydrophobic coating;

• Volatility: non-volatile (does not evaporate);

• Purpose: designed to protect electronics from water, moisture, short circuits, corrosion, salts, mold and dust, and also helps to dissipate heat better;

• Total weight: 67.2 g.

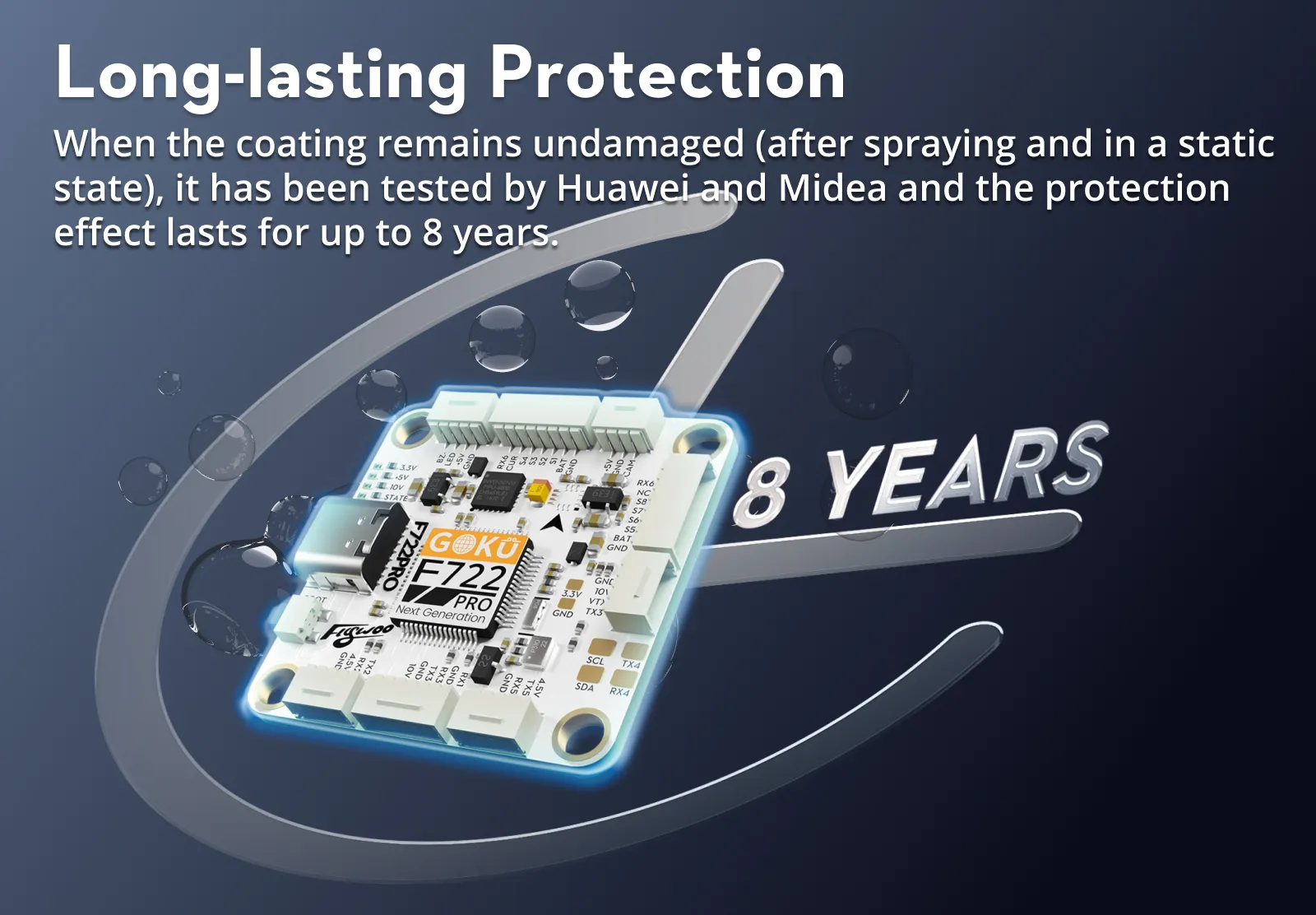

Long-lasting Flywoo X30 protection

Long-lasting Flywoo X30 protection

If the protective coating remains intact (after spraying and in a stationary state), according to tests conducted by Huawei and Midea, its protective effect can last up to 8 years. When used on drones, the coating may be damaged due to shocks, vibrations or other possible damage during flight, so it is recommended to re-coat the surface before each flight.

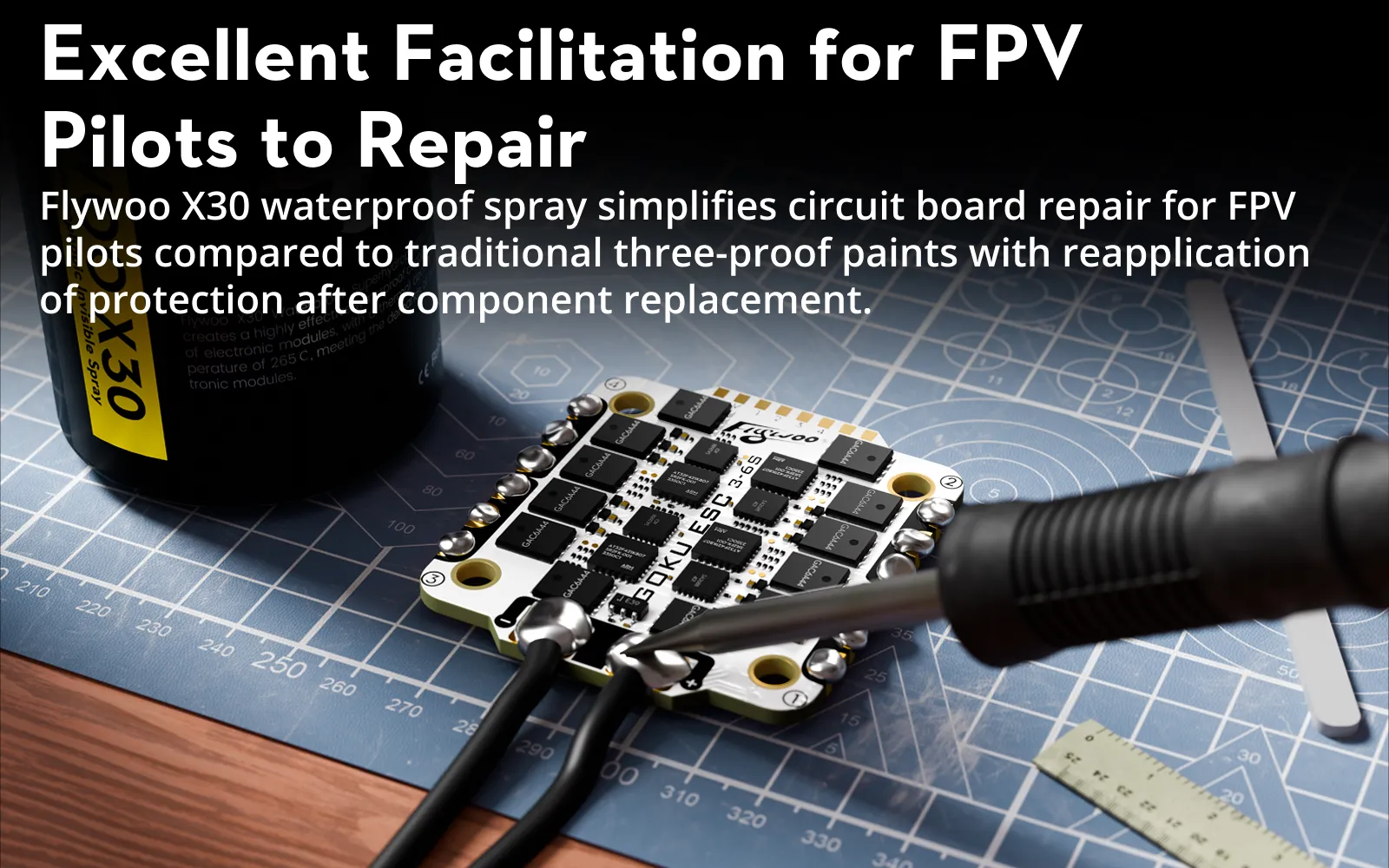

A convenient solution for FPV pilots when repairing electronics

A convenient solution for FPV pilots when repairing electronics

Flywoo X30 Waterproof Spray makes electronic board repairs much easier for FPV pilots compared to traditional protective varnishes. After replacing components, there is no need for complicated re-varnishing - the protective coating can be quickly renewed with a simple spray.

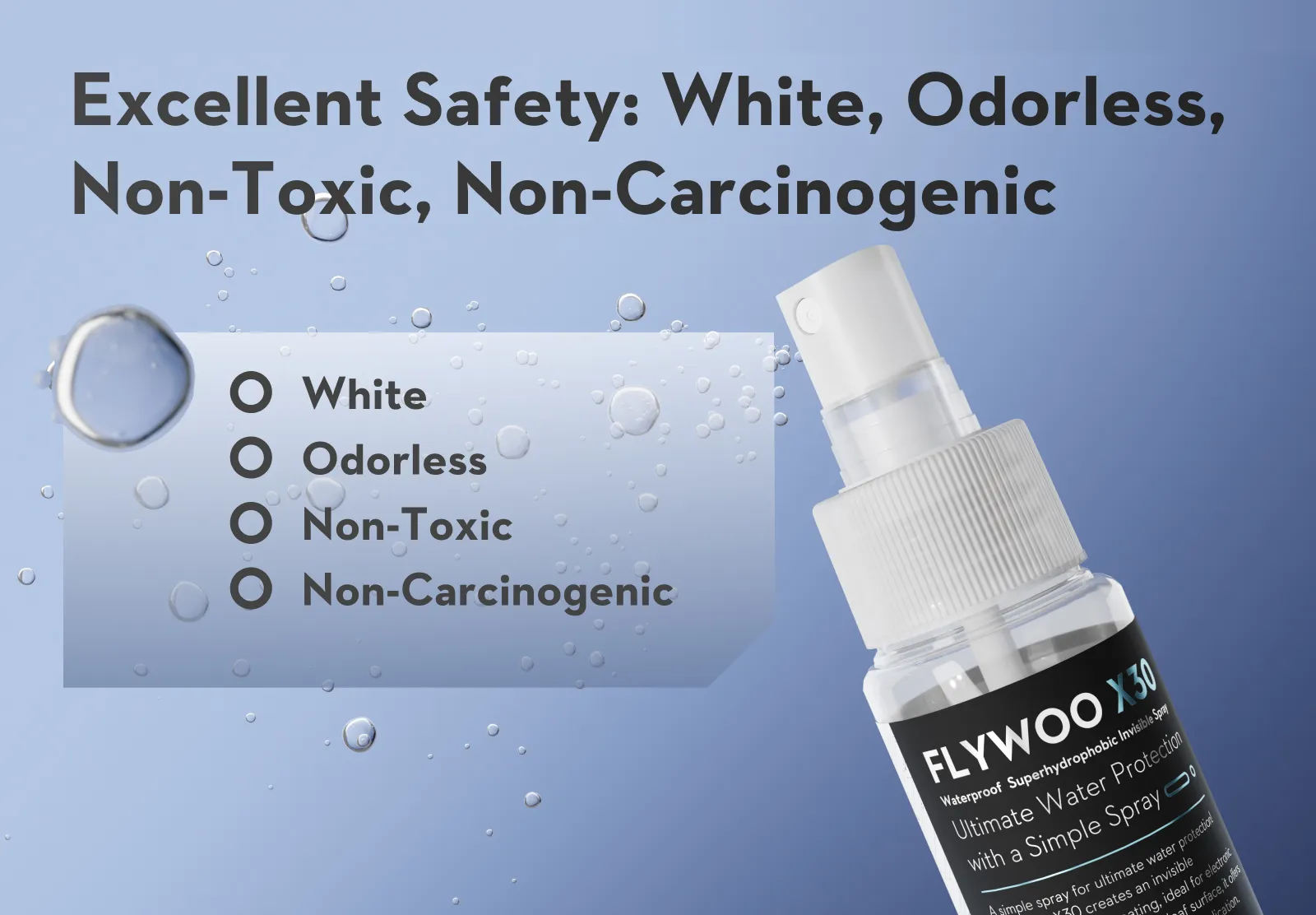

Free from harmful substances

Free from harmful substances

Flywoo X30 Waterproof Spray is environmentally friendly and free of harmful substances. Meanwhile, traditional protective varnishes can emit volatile organic compounds (VOCs), which have a negative impact on both the environment and human health.

Comparison with traditional protective varnishes

Comparison with traditional protective varnishes

The effectiveness of traditional "triple protection" varnishes depends largely on the tightness of the coating - this is precisely the main goal of research and development of such manufacturers.

Meanwhile, superhydrophobic coatings inherently have natural properties: protection against water, short circuits, corrosion, salts, mold, and dust. This makes superhydrophobic materials a great alternative to traditional protective varnishes.

| Electronics industry needs | Superhydrophobic coating | Traditional protective coating (Conformal) |

|---|---|---|

| Water resistance | The main property of a superhydrophobic coating is its natural water resistance. | Depends on the density of the coating layer |

| Short circuit protection | Excellent protection due to repellency of water, moisture and corrosive liquids | Depends on the density of the coating layer |

| Corrosion protection | Naturally repels water and corrosive liquids, providing excellent protection | Depends on the density of the coating layer |

| Resistance to salt exposure (salt fog) | Excellent protection due to natural salt repellency | Depends on the density of the coating layer |

| Mold resistance | Hydrophobic and dry surface that does not create conditions for bacteria and mold | Anti-mold additives must be added, which can impair the tightness of the coating |

| Dust resistance | „"Self-cleaning" effect like a lotus leaf - prevents dust from accumulating | No dust protection |

| Heat dissipation | Inorganic-organic composite coating helps to dissipate heat better | Polymer coatings dissipate heat worse |

Excellent performance indicators

The superhydrophobic coating was tested on the surface of Huawei's 5G base station printed circuit board (PCB). It passed three stages of pre- and post-exposure testing, and the results showed that its protective properties are significantly better than 3M's traditional protective varnishes.

Huawei test comparison: superhydrophobic coating vs. 3M

| Comparison criteria | X30 superhydrophobic coating | 3M protective varnish |

|---|---|---|

| Layer thickness | ~20 µm | ~40 µm |

| Contact angle | 160° | 80° |

| Water humidification | Completely non-wetting | Partial humidification |

| Wet/Dry Cycles | After 1000 cycles, the contact angle remained unchanged | After 100 cycles, the contact angle decreases to 30° |

| Resistance to salt fog | 1000 hours. | 500 hours. |

| Grip level | Level 0 | Level 0 |

| Short circuit protection (accelerated test in salt spray chamber) | 1500 hrs. | 1000 hours. |

Based on the data above, this superhydrophobic coating clearly outperforms 3M's traditional protective coating in several key indicators:

1. Thinner layer – 20-50 µm is sufficient for a superhydrophobic coating, while a traditional coating requires 40-120 µm.

2. Greater hydrophobicity – the contact angle reaches 160°, while 3M coatings only have 80°, so water is repelled much more effectively.

3. Longer lasting effect – after 1000 cycles of wetting and drying, the properties of the superhydrophobic coating did not change, while the 3M coating lost its effectiveness after just 100 cycles (the contact angle decreased to 30°).

4. Better corrosion and short circuit protection – the superhydrophobic coating withstood 1000 hours of salt spray testing and 1500 hours of short circuit protection, compared to 3M’s ratings of 500 hours and 1000 hours, respectively.

These properties make superhydrophobic coatings an excellent protective solution for the electronics industry. Their thin layer, extremely strong water repellency, and exceptional durability make them a far superior alternative to traditional protective coatings.

Excellent heat dissipation

Traditional protective coatings have a layer thickness of 40-120 µm, while X30 Super Hydrophobic Coating only requires 20-50 µm. The thinner layer allows heat to escape from electronic components faster, reducing the risk of overheating.

| Material type | Acrylic resin | Epoxy resin | Silicone resin | Polyurethane resin | P-xylene | X30 superhydrophobic materials |

|---|---|---|---|---|---|---|

| Thermal conductivity (W/mK) | 0.2–0.8 | 0.2–1 | 0.8–1.2 | 0.35–1.1 | 0.2–0.5 | 3,3 |

| Thermal resistance (10⁻⁴ m²K/W) | 1–4 | 0.8–4 | 0.6–1 | 0.7–2.2 | 1.6–4 | 0,1 |

The comparison data shows that the X30 superhydrophobic material has an extremely high thermal conductivity of 3.3 W/mK, which significantly exceeds that of conventional resin coatings. In addition, its thermal resistance is only 0.1 × 10⁻⁴ m²K/W, making it extremely efficient at transferring heat.

This means that compared to traditional coatings, our superhydrophobic coating is significantly better at dissipating heat, improving the cooling and overall thermal efficiency of electronic devices. This is especially important for high-power electronic devices that require reliable heat dissipation.

In conclusion, due to its excellent thermal conductivity properties, this superhydrophobic coating ensures better cooling of electronics and is an ideal protective measure.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.